The bearing includes a fixed type used at the fixed end and a movable type used at the free end. As to which type to choose is dependent on the actual situation. The movable bearing can compensate for the deformation caused by the thermal expansion of the shaft.

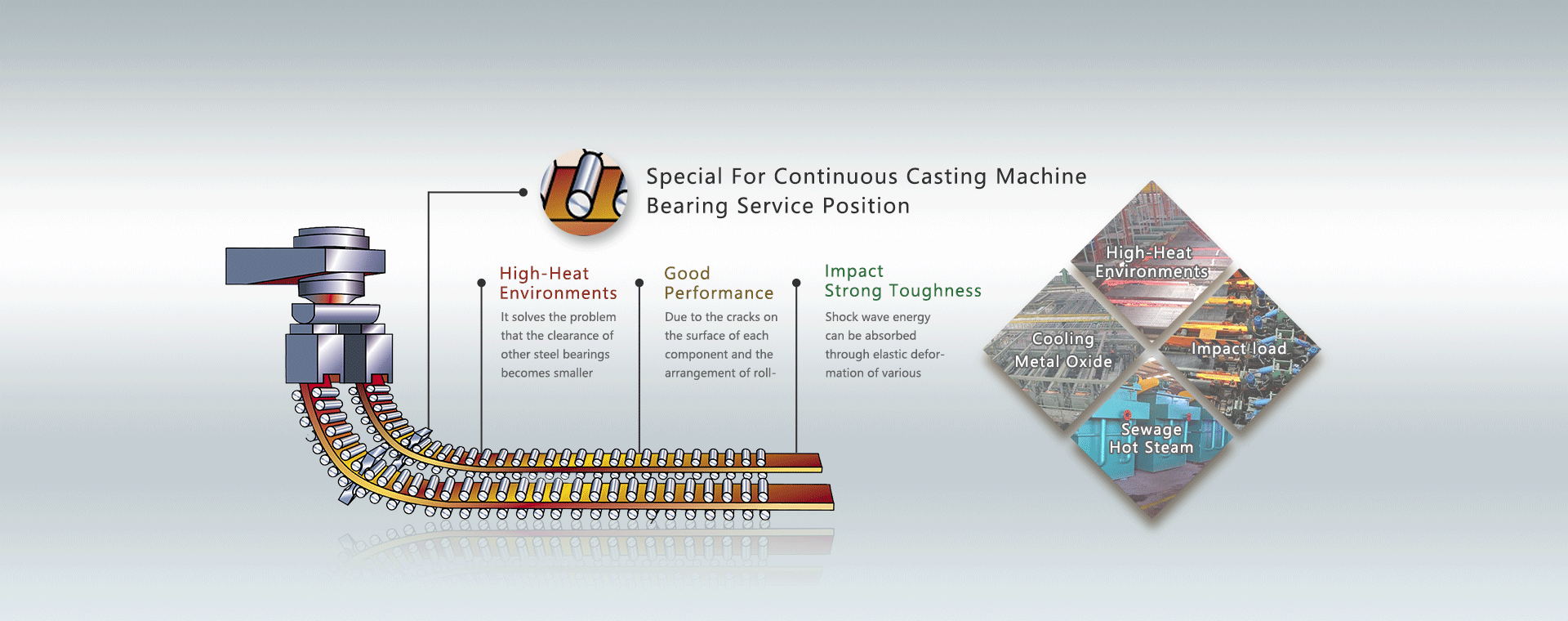

The spiral ring roller bearings produced by our Company are applicable in the high-temperature working area. When its temperature reaches 300℃, the bearing can still bear shock vibration load, ensuring the operation accuracy of the equipment.

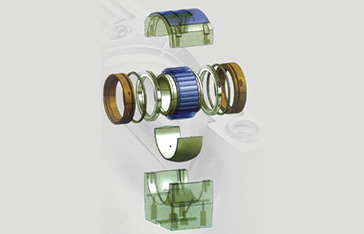

The bearing comes in with either full-complement or holder-supported structure. After installation, the angle error is allowed between inner and outer rings, which does not impair the bearing performance.

The split bearing only has half of aligning outer ring. Its outer raceway is processed in the upper part of the bearing seat. In the seat stands a circulating water-cooling chamber which ensures the bearing works normally under high-temperature working conditions.

This bearing is provided with aligning function due to its spherical outer ring, which is immune to the roller bending and installation error. It is of either fixed-end or free-end structure. Its load measures 1.25 times of the similar-sized self-aligning roller bearing. Besides, as it has the same outline size with the self-aligning roller bearing, they are interchangeable.

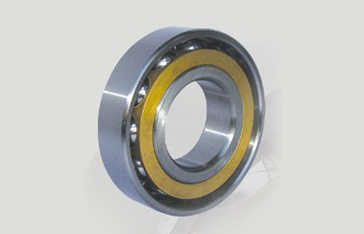

The bearing feature double rows of rollers with high radial load capacity, which is accordingly applicable to work under heavy load or shock load. It can bear the axial load from any direction rather than bear pure axial load. Furthermore, the bearing, due to its excellent aligning function, is able to compensate coaxiality error resulting from bending deflection and improper mounting location so that it is widely used in heavy machinery in metallurgy, mine and maritime transport fields.

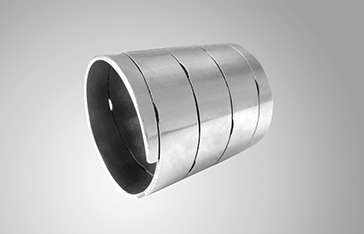

As there is no retainer ring for the inner ring of the bearing, the inner and outer rings can be installed separately. Its structure disables to limit the axial displacement of itself and its shell and only enables to bear the radial load. Its ring is usually not reserved with lubrication hole. If required by the client, the hole may be processed in the inner or outer ring. After high-temperature tempering treatment of its components, the bearing can work normally at about 300℃.

Two locating slots are symmetrically arranged at protruding end of the inner ring to limit the relative rotation between the inner ring and the bearing.

ADAPT bearing integrates the features of both traditional cylindrical roller bearing and self-aligning roller bearing. It is designed with distinct bearing outer ring raceway, patching roller and cylindrical inner ring. The full-roll design maximizes the carrying capacity of bearing.

The cylindrical roller bearing structure is able to effectively restrain the internal sliding of the bearing, and to absorb the deflection of the continuous caster roller by virtue of its well-designed convexity, thus contributing to is long service life.(The maximum tilt limit is 12min)

Made of spring steel, the shaft sleeve has excellent elastic properties and will not be deformed even under extreme conditions.

Through the high temperature processing, the beating can work normally at about 300℃.

This bearing, a popular one, is of non-separable type and has high rotating speed. It is mainly used to bear radial load and also a certain axial load, and is suitable for high rotating speed.

The bearing can be used as an axial positioning bearing when used with four-row cylindrical roller bearings of rolling mill. However, the two sets must be matched in a back-to-back (he wide end faces of the outer ring are opposite) or face-to-face (the narrow end faces of the outer ring face each other) manner.

Tapered roller bearing is of a separated type, which mainly bear combined radial and axial loads. The axial bearing capacity depends on the raceway angle of the outer ring, so greater bearing capacity comes with greater angle. As single row tapered roller bearing can only bear axial force in one direction, so two sets must be used together.

The bearing is based on a shaft with oil holes, with a thick-walled outer ring roller bearing installed radially and a needle roller bearing installed on the shaft side. It can bear large radial load and axial impact load in a single direction

Copyright ? 2018 - Benxi Metallurgy Bearing Co., Ltd Serive Support - Bearing.cn